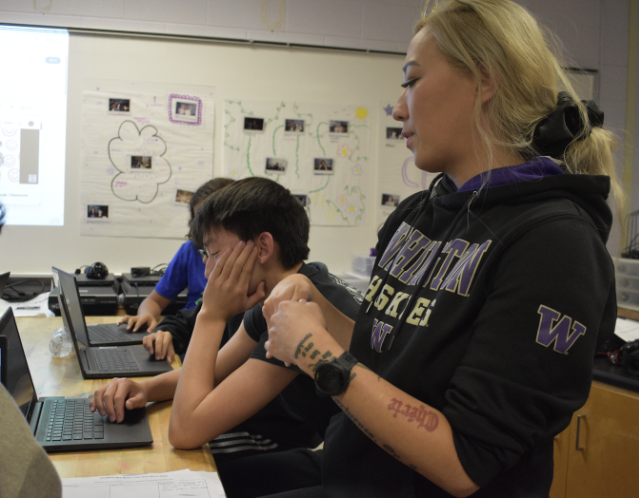

Most classes don’t get the opportunity to learn in a self-paced environment, practice what they learn in a hands-on way and use those skills to fix what’s broken in exchange for a profit. And yet, this is exactly what the auto technology and auto collision classes do every day.

Students in these auto classes spend their days learning the ins and outs of automobile repair through firsthand experience. Approximately 25 donated cars reside in the alleyway behind the school, waiting for repairs.

“We have cars that are donated to us so just like any other nonprofit organization, we’re able to provide that tax write off for those individuals,” academy administrator Scott Settar said. “Our teachers assess the cars and between our auto technology and auto collision program, they do the repairs on the car.”

According to Auto Tech 2 junior Jack Evans, there are three main categories a car may fall into: student auto sales (SAS), personal projects and junk cars.

“A lot of the time, they’ll either be in a condition where we want to sell them so those issues tend to be more minor things,” Evans said. “The cars that we just use to play with are cars that are beyond repair, so that’s not something that we can repair without spending tons upon tons of money for it to work.”

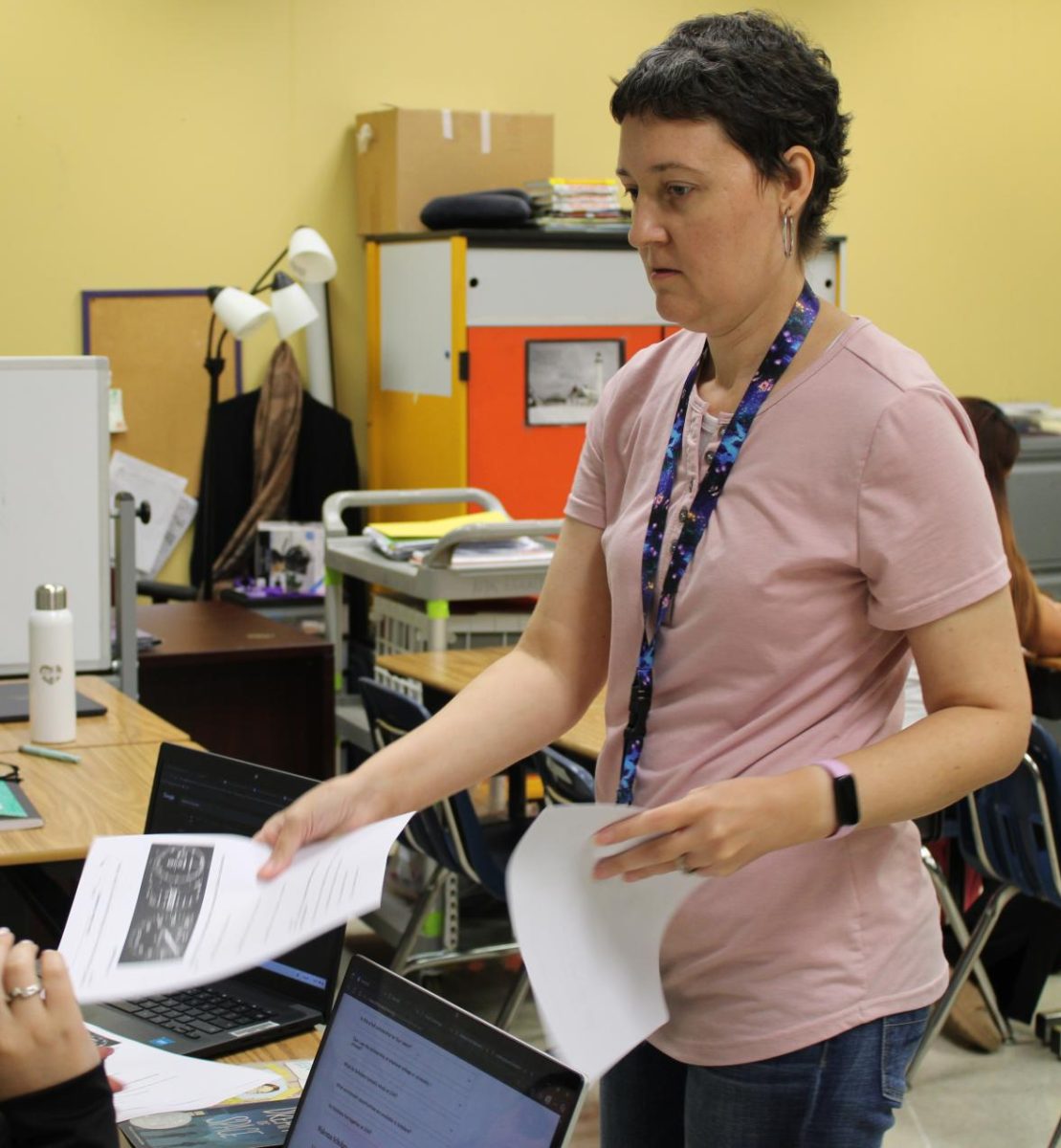

In addition, if a student or their friend has a car which needs repairs or maintenance done, they may also bring it in. From there, students and staff use a diagnostic checklist to determine how to proceed.

“Once we get those in, I have my students go through a checklist—basically if everything works, what’s wrong with it and we determine the value, if it is worth putting money in to fix it to resell,” auto collision teacher Ryan Byrne said. “The students work on student auto sales cars and if they have a personal project.”

The auto program has two main streams of income: SAS cars and detailing jobs. When there are no issues with a vehicle and it just needs a basic tuneup, auto tech students charge $25-$30 for a detailing job.

“It comes in and we start with the interior detail, then the engine compartment and then we come to the outside and do a wash, buff, polish and a wax, plus your tire shine and what not,” Byrne said. “I’ve never had anybody want to bring a motorcycle in [but] if it has wheels, I’m willing to detail it.”

Though students do not receive payment for their work, the money made through SAS and detailing goes directly back into the auto program. Pieces, parts and disposable resources are all purchased in part with the capital earned by the students.

“We purchase parts and material through various vendors just like you would at home,” Settar said. “We have a contract with different vendors so we get parts at a discounted price; so a part that might cost $100 for you, costs $25 for us.”

CHS staff and students may email Byrne ([email protected]) if they are interested in receiving a detail or repair.Byrne and his students are able to work on all vehicles except one type: electrics.

“It is against our policy so we are not allowed to have any hybrid vehicles down here,” Byrne said. “We can go through the electric system of a 12 volt which is your normal gasoline cars and diesels.”